RBRquartz3 APT Ethernet Home

Summary

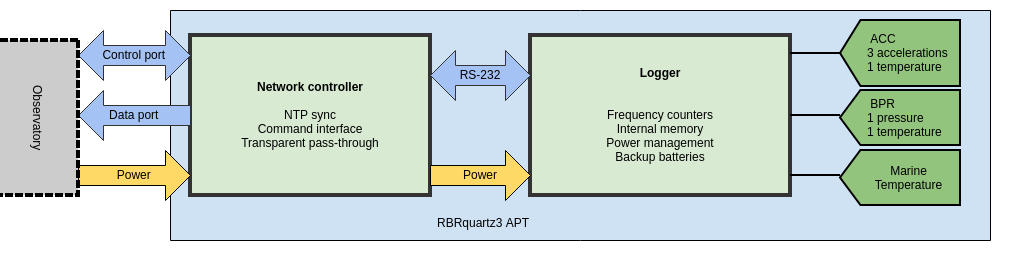

The RBRquartz3 APT is a deepwater high-resolution bottom pressure recorder and triaxial accelerometer, capable of both observatory-connected and autonomous measurements at 16Hz. Data is always recorded internally, but may also be streamed in real-time over the Ethernet connection.

The hardware structure of the instrument is shown in the block diagram below.

Connections

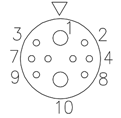

The MINK connector is wired for Ethernet and power.

Face view of the male MINK connector on the RBRquartz3 APT:

Connector pinouts are shown in the table below:

| Pin # | Description |

|---|---|

| 1 | PWR (min 9V max 17V) |

| 2 | ETHERNET TX+ DATA TO RBR |

| 3 | ETHERNET RX+ DATA FROM RBR |

| 4 | ETHERNET TX- DATA TO RBR |

| 5 | N.C. |

| 6 | N.C. |

| 7 | ETHERNET RX- DATA FROM RBR |

| 8 | N.C. |

| 9 | N.C. |

| 10 | GND |

IP connections to the instrument are made on two different ports. The first is the data port (23) which is a read-only socket where the client should simply listen for the measured data that is being streamed out. The second is the control port (2323) which permits some settings to be modified.

Performance and timing considerations

Logger

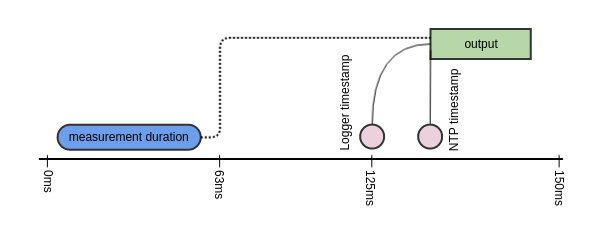

Logger readings will be timestamped no earlier than 63ms and no later than 125ms from when the reading was completed. The resolution of logger timestamps is 63ms. Logger output of the timestamped sample will occur within 63ms of the indicated timestamp.

NTP-based tagging

The network controller associates each sample received from the logger with an NTP-based timestamp upon receiving the first character of the line of data from the logger. The resolution of NTP-based timestamps is 5ms. After receiving the entire sample, it is sent to the TCP connection within 5ms.

Starting up for the first time

In order to start the logger, use the transparent mode in the control interface and the following commands. These assume that the logger clock has been reset already, if of interest ( clock command).

deployment starttime = 20000101000000, endtime = 20991231235959

sampling mode = continuous, period = 63

enable erasememory = trueConfiguring network settings

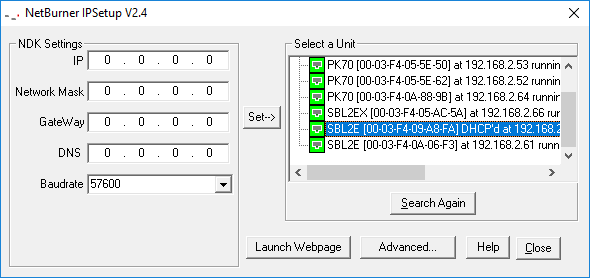

To configure the network controller, a Windows-only executable is required to run on a host on the same subnet (same UDP broadcast domain) as the instrument.

In its default state, the instrument will attempt to acquire network configuration information via DHCP. Using IPSetup, the static IP address, network mask, gateway, and DNS server of the instrument can be configured. No other settings in IPSetup should be changed at risk of an invalid configuration requiring the instrument to be returned to RBR for service.

Periodic stop-erase-start procedure

disable

enable erasememory = trueAs the instrument has a linear memory, in order to provide protection for a possible network outage it is important to periodically stop the logging, erase the memory, and restart. This process should take less than ten seconds, during which there will be no streaming data, nor logged data. As the logger memory will fill in ~25 days, this process should be followed every 20 days (or 3 weeks) to give some margin for human error.

Procedure after an observatory outage

<download while still running - may take hours or days>

// chunksize := 500

// offsetdataread := 0

>> meminfo

<< meminfo used = YYY

// totalsize := YYY

// while (offsetdataread < totalsize) {

// while (offsetdataread < totalsize) {

>> readdata dataset = 1, size = chunksize, offset = offsetdataread

<< readdata dataset = 1, size = nbytesread, offset = 2000 offsetread<cr><lf><bytes[0…nbbytesread]-of-data><crc>

// if crc ok

// {

// append bytes read to output file

// offsetdataread := offsetdataread + nbbytesread

// }

// }

>> meminfo

<< meminfo used = YYY

// totalsize := YYY

// }

<end of download>

>> disable

>> enable erasememory=trueThe download can be performed by reading all the bytes in dataset 1 and writing them in a *.bin file. Ruskin is able to read directly those files.

For more details on the read and meminfo commands and the CRC calculation, please refer to the L3 command reference.

Stopping the instruments and preparing for shipment

disableThe only command required to be sent to the logger (using the transparent mode in the control interface) is disable. The control interface will still be active but may be powered down by removing the MINK cable. The internal batteries will continue to provide backup power to the logger RTC (~10uA) and will last for many years in this state.

Control port commands

Upon connection to the control port (2323), there will be no immediate response nor banner. If the command required is known, it can be entered immediately (all commands are terminated with line-feed, and any carriage returns are ignored). If the commands are not known, the question mark ("?") command can be used to display the network controller control menu.

The control port connection supports a single connection. It is important that the connection is closed after use, permitting others to establish connections if necessary.

------ RBRquartz3 APT NETWORK INTERFACE CONTROL MENU ------

D: Display current settings

S: Set NTP source

R: Set NTP refresh rate

J: Set the timestamp jump tolerance

E: Set the transparent mode inactivity timeout

T: Enter transparent mode

!: Exit transparent mode (once in transparent mode)

Q: Close this connection

#: Reset the RBRquartz3 APT network interface

?: Print this menuD: Display current settings

RBRquartz3 APT Network Interface v1.5.1

Uptime: 0 days 00:13:03.340

Current time: 2021-05-10 15:11:48.248

System parameters

-----------------

NTP time sync rate (min): 1

NTP source: NTP pool

Timestamp jump tolerance (s): 1800

Transparent mode inactivity timeout (s): 10

Last valid time sync: 2021-05-10 15:11:02.934The current settings shown include

- Uptime: approximate time since the last reboot - either due to power up or the

#reset command. - Current time: this clock is maintained according to the NTP settings.

- NTP time sync rate: frequency at which the NTP source is polled to correct for clock drift. See

Rcommand. - NTP source: Either the IP address of the NTP server or the phrase “NTP pool”. See the

Scommand. - Timestamp jump tolerance: time tolerance in seconds for the difference in the logger clock between two subsequent samples. (Only when the new sample is in the future)

- Transparent mode inactivity timeout: timeout for leaving transparent mode if no input is received in the set amount of time.

- Last valid time sync: the last time at which a successful poll of the NTP source occurred.

S: Set NTP source

Enter NTP source (IP address, a.b.c.d).

To use pool.ntp.org, enter 0.By default, the NTP Pool will be used as the source of NTP times. A custom NTP server can be used by providing its IP address.

Whenever this value is changed, an NTP poll is performed immediately and the schedule for polling is restarted.

R: Set NTP refresh rate

Enter the NTP refresh rate (number of minutes, 1-60; default: 1):The frequency with which time is polled from the NTP source can be adjusted.

Whenever this value is changed, an NTP poll is performed immediately and the schedule for polling is restarted.

J: Set the timestamp jump tolerance

Enter the timestamp jump tolerance (number of seconds, 1-86400; default: 1800):The time tolerance between two subsequent instrument samples to trigger a clock sync with the logger. This will accommodate cases where the logger is reconfigured externally.

E: Set the transparent mode inactivity timeout

Enter the transparent mode inactivity timeout (number of seconds, 10-60; default: 10):The time for exiting transparent mode automatically if no commands are issued in that time frame.

T: Enter transparent mode

Data streaming off

Transparent mode onTo communicate with the instrument directly, use the T command to enter transparent mode. Upon entering transparent mode, the instrument's streaming output will be automatically disabled. While in transparent mode no output will be sent to the data client; however, any connections to the data port will remain open and will resume receiving data when transparent mode is closed. Upon leaving transparent mode, the streaming output of the instrument will be automatically re-enabled (providing that the instrument is enabled).

There are two ways of leaving transparent mode: manually escaping with the ! character (described below), and an automatic configurable idle timeout. If 10 seconds, or the set time, elapse without characters being received by the network controller, transparent mode will automatically be closed and streaming output will be restarted.

Transparent mode is maintained across multiple control client connections. If the control client is disconnected without escaping from transparent mode (i.e., by abruptly terminating the socket connection), future connections will be placed directly into transparent mode (unless the idle timeout has been exceeded).

!: Exit transparent mode (once in transparent mode)

Data streaming on

Transparent mode offWhen in transparent mode, send a ! character to immediately leave the mode and restart instrument streaming.

See the notes for the T command for details on the behaviour of the data port upon leaving transparent mode.

Q: Close this connection

Connection closed by foreign host.Explicitly close the connection to the control port.

#: Reset the APT network controller

Resetting server. All connections will be lost!

Connection closed by foreign host.The control interface is reset by this command, a process that takes <10s. All network connections are lost and will have to be re-established. The network controller clock is reset to the beginning of 1970, but the first NTP sync should be done by the time the first connection is made.

?: Print this menu

Displays the menu as shown above.

Data port format

The data port provides read-only data and does not respond to any commands.

Sample data

The format of the data is as follows:

Sample data example

2021-05-06 19:03:37.924, 2021-05-06 15:03:37.000, 29743852.000000000, 31061098.000000000, 29998406.000000000, 5890331.000000000, 26.141700000, 9.235400000, 25.397600000, 30284722.000000000, 5752694.000000000

2021-05-06 19:03:38.924, 2021-05-06 15:03:38.000, 29743852.000000000, 31061098.000000000, 29998406.000000000, 5890331.000000000, 26.141700000, 9.234300000, 25.397000000, 30284722.000000000, 5752694.000000000

2021-05-06 19:03:39.924, 2021-05-06 15:03:39.000, 29743854.000000000, 31061098.000000000, 29998406.000000000, 5890331.000000000, 26.141700000, 9.232900000, 25.396600000, 30284722.000000000, 5752694.000000000| # | Name | Format | Notes |

|---|---|---|---|

| 1 | Logger time NTP offset corrected | YYYY-MM-DD HH:MM:SS.sss format. | The time that the internal logger reports corrected with the latest NTP offset. The current NTP time may be examined using the D command via the control interface. |

| 2 | Logger time | YYYY-MM-DD HH:MM:SS.sss format. | The time that the internal logger reports. This clock may be read and set using the now command via transparent mode. Drift should be ±60s/year. |

| 3 | Accelerometer X period (ps) | Double precision (64 bit) floating-point number. | The period of the X (first) channel of the triax accelerometer. |

| 4 | Accelerometer X period (ps) | Double precision (64 bit) floating-point number. | The period of the Y (second) channel of the triax accelerometer. |

| 5 | Accelerometer X period (ps) | Double precision (64 bit) floating-point number. | The period of the Z (third) channel of the triax accelerometer. |

| 6 | Accelerometer temperature period (ps) | Double precision (64 bit) floating-point number. | The period of the temperature (fourth) channel of the triax accelerometer. |

| 7 | BPR temperature (C) | Double precision (64 bit) floating-point number. | The temperature derived from the second channel of the BPR. |

| 8 | BPR pressure (dbar) | Double precision (64 bit) floating-point number. | The pressure derived from the (first) channel of the BPR. |

| 9 | Temperature (°C) | Single precision (32-bit) floating-point number | The temperature measured by the RBR thermistor. |

| 10 | BPR pressure period (ps) | Double precision (64 bit) floating-point number. | The period of the pressure (first) channel of the BPR. |

| 11 | BPR temperature period (ps) | Double precision (64 bit) floating-point number. | The period of the temperature (second) channel of the BPR. |

One variation to the normal data format will occur when an internal error occurs. This error usually happens on a single channel at a time, and is most often caused by a failed electrical connection so that no valid readings are available. If this occurs, it will look like the following:

Sensor errors example

2021-05-06 19:03:39.924, 2021-05-06 15:03:39.000, Error-9, 31061098.000000000, 29998406.000000000, 5890331.000000000, 26.141700000, 9.232900000, 25.396600000, 30284722.000000000, 5752694.000000000All errors should be reported to RBR for investigation.

Events

All events obey the following format:

Abnormal data - spike correction

#EVENT_NAME, timestamp, eventPayload1, eventPayload2, ..., eventPayloadn- 1, eventPayloadnEVENT_NAME is a string name for the event

timestamp is the time at which the event occurred; depending on the event type, this may correspond to a corrected sample time

eventPayload1—eventPayloadn are the payload values for the event

NTP synchronization events

When an NTP synchronization occurs, one event #NTPSYNC event will be generated on the output:

#NTPSYNC, which corresponds to an NTP offset adjustment; its timestamp is the logger time for the sample on which synchronization occurred corrected with the new NTP offset, eventPayload1 is the logger time for the sample on which synchronization occurred, and eventPayload2 is the new NTP offset in milliseconds.

NTP synchronization event example

2021-05-06 19:03:38.924, 2021-05-06 15:03:38.000, 29743852.000000000, 31061098.000000000, 29998406.000000000, 5890331.000000000, 26.141700000, 9.234300000, 25.397000000, 30284722.000000000, 5752694.000000000

#NTPSYNC, 2021-05-06 19:03:39.924, 2021-05-06 15:03:39.000, 924

2021-05-06 19:03:39.924, 2021-05-06 15:03:39.000, 29743854.000000000, 31061098.000000000, 29998406.000000000, 5890331.000000000, 26.141700000, 9.232900000, 25.396600000, 30284722.000000000, 5752694.000000000Power consumption

The power consumption when the external power is present is ~1.5W continuous.

Battery life

The logger will switch to its internal battery and continue recording when external power is not present. The network controller will shut down automatically under this condition.

There is enough internal batteries for the logger to continue recording for 250 hours (~210 mW power consumption in such case).

Maintenance

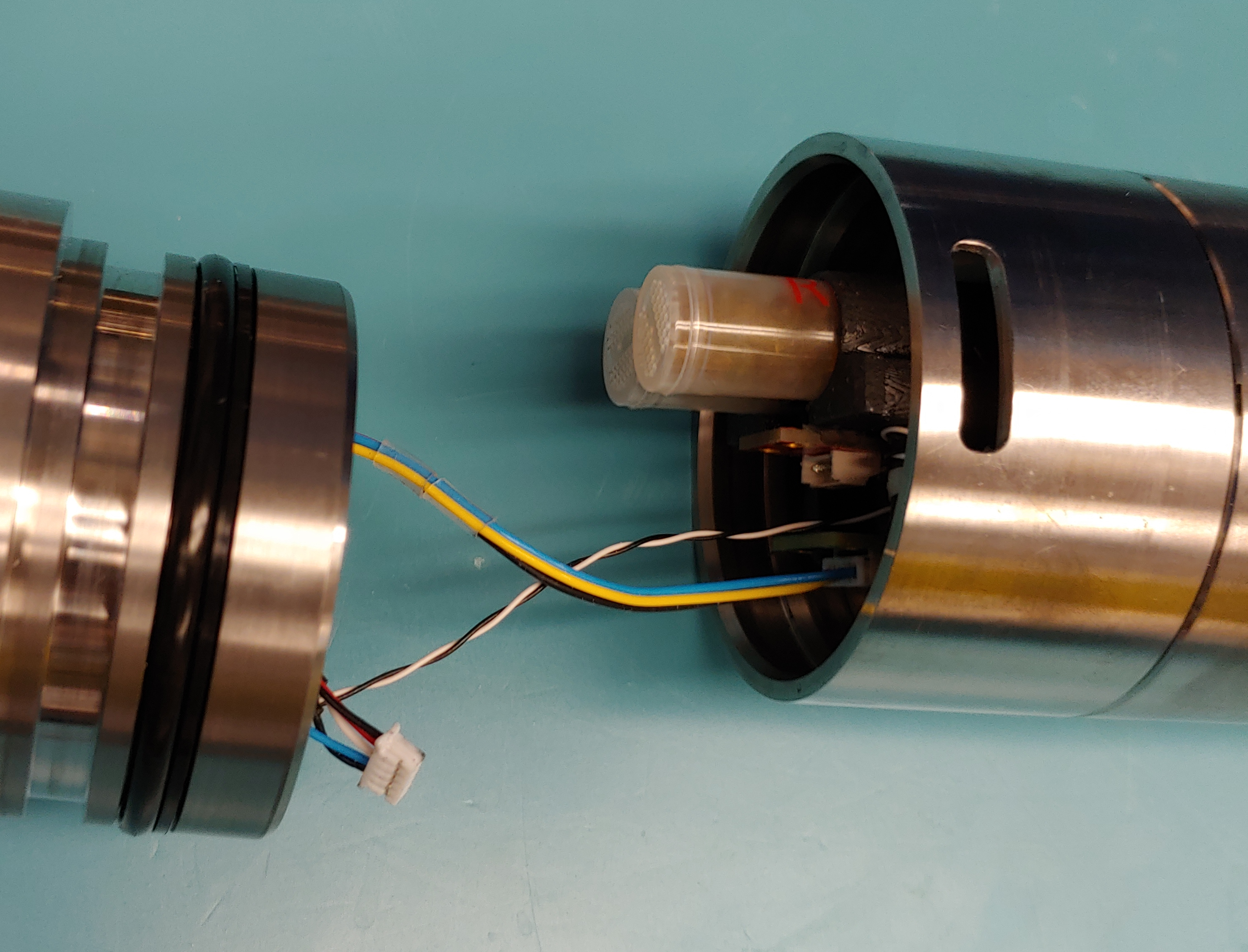

How to disassemble the housing

IMPORTANT: Do not unscrew housings while the two halves of the instrument are together; unscrewing will twist sensitive wire assemblies inside the instrument and damage them.

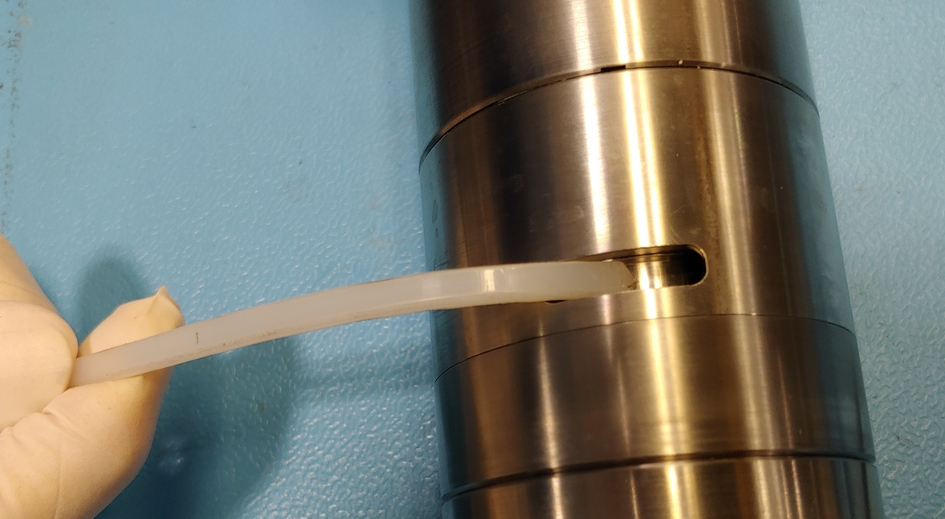

- Locate the nylon locking strap located approximately halfway down the outside of the instrument. One side of the nylon has a hole in it. Using a pair of pliers pull the nylon strap out of its locking groove by the end with the hole in it.

- It is normal to have a little o-ring grease on this strap to help with its insertion/removal from the groove

- It is normal to have a little o-ring grease on this strap to help with its insertion/removal from the groove

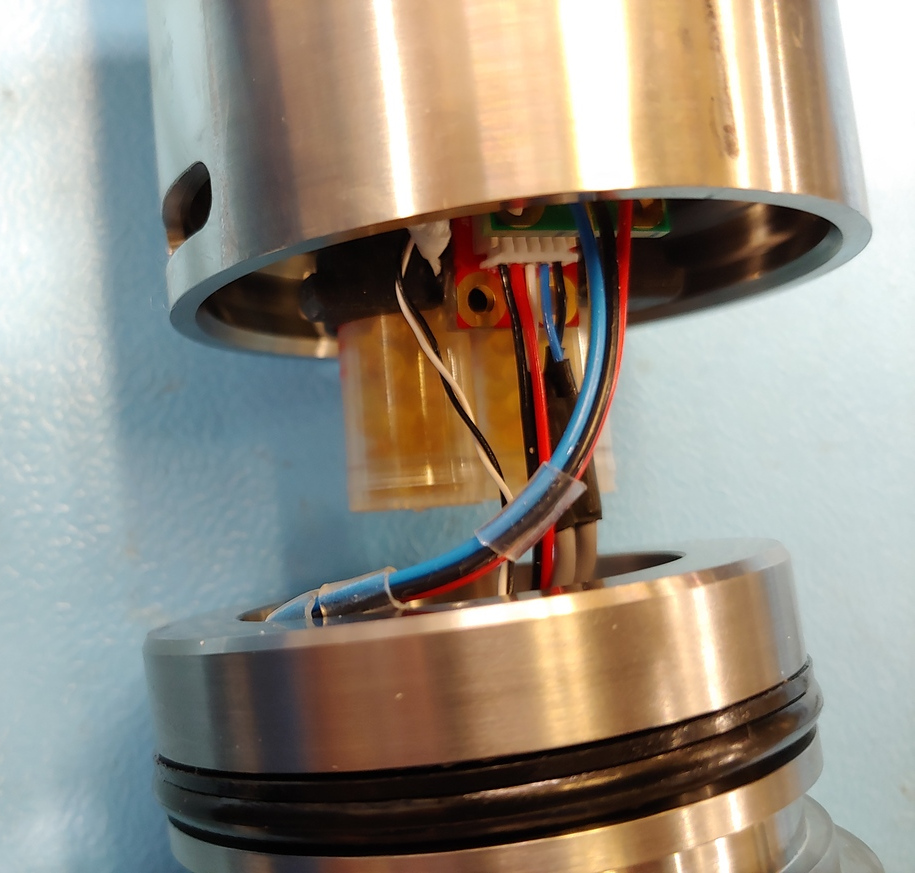

- The two halves can now be gently pulled apart. The wire assemblies allow for about 60mm of distance between the two halves.

3. Using tweezers or plastic spudgers, separate the wire assembly connectors from the PCBs. Do not pull by the wires, it is easy to pull the wires from their crimps.

4.Once the two-wire assemblies are disconnected the two halves of the instrument can be handled independently.

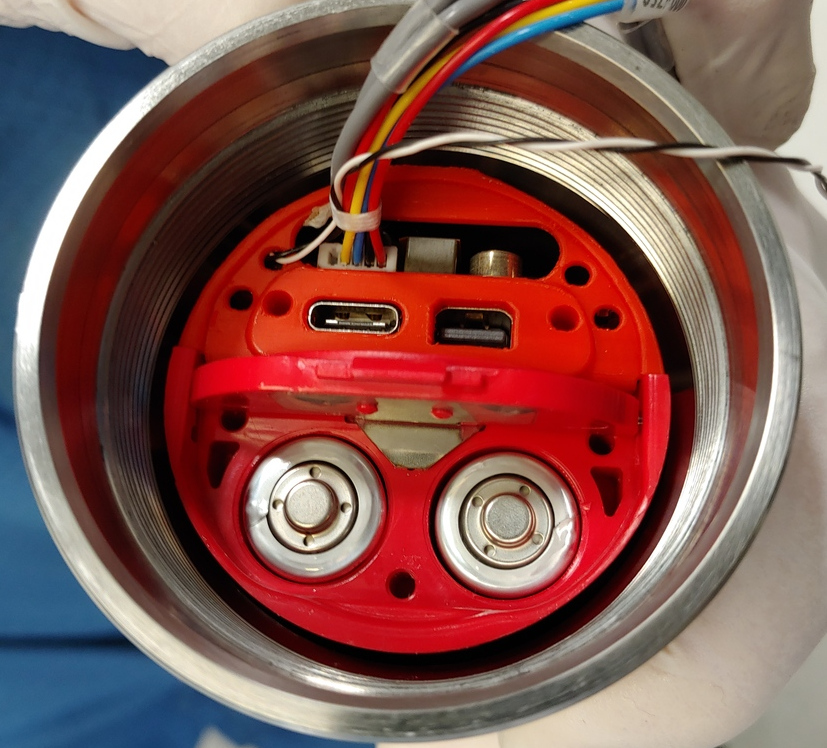

How to change the batteries

- Disassemble the housing as described above.

- The half of the instrument with the nosecone contains the accelerometer, battery carriage assembly, CPU and its power supply.

- Unscrew the coupling piece to expose the battery carriage assembly.

4. The door may be opened by pushing the door to unlatch it and sliding the door up; the door will open as shown.

5. Remove eight AA batteries.

6. Replace with eight new AA batteries, be sure to install all batteries with the positive end towards the battery door.

7. Close the battery door again.

8. Check the coupling housing o-ring to ensure that it is clean, undamaged, and properly lubricated.

9. There should be no cuts, nicks, or excessive flashing.

10. The o-ring should be slightly lubricated with silicone o-ring grease.

11. Check the threads on the housing and the coupling housing to ensure they are clean and undamaged.

12. Screw the coupling housing back onto the instrument half with the nosecone.

13. Reassemble instrument as described below.

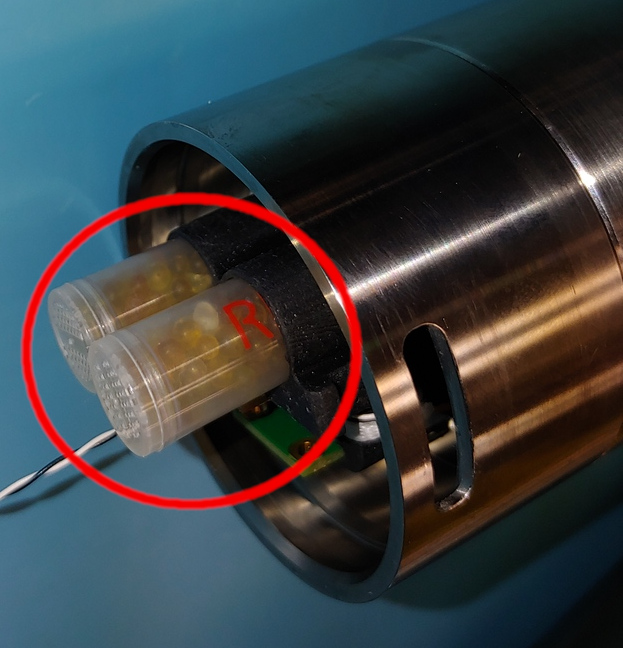

How to change the desiccant

- Disassemble the housing as described above.

- The half of the instrument with the MINK connector contains two desiccant capsules.

- Remove the old capsules by gently pulling them from the plastic carriage.

- Push two new capsules into the plastic carriage.

- Reassemble unit as described below.

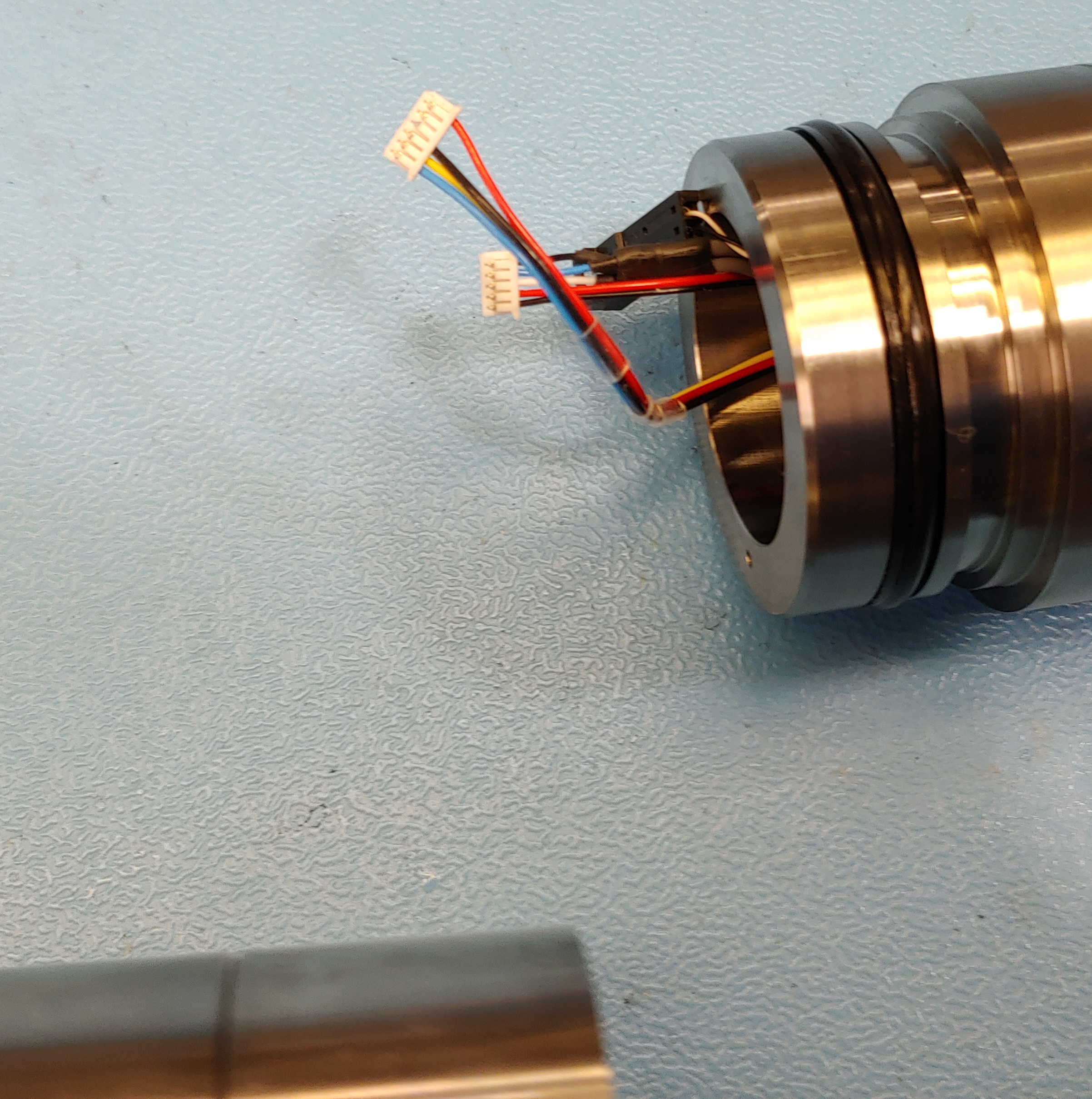

How to reassemble the housing

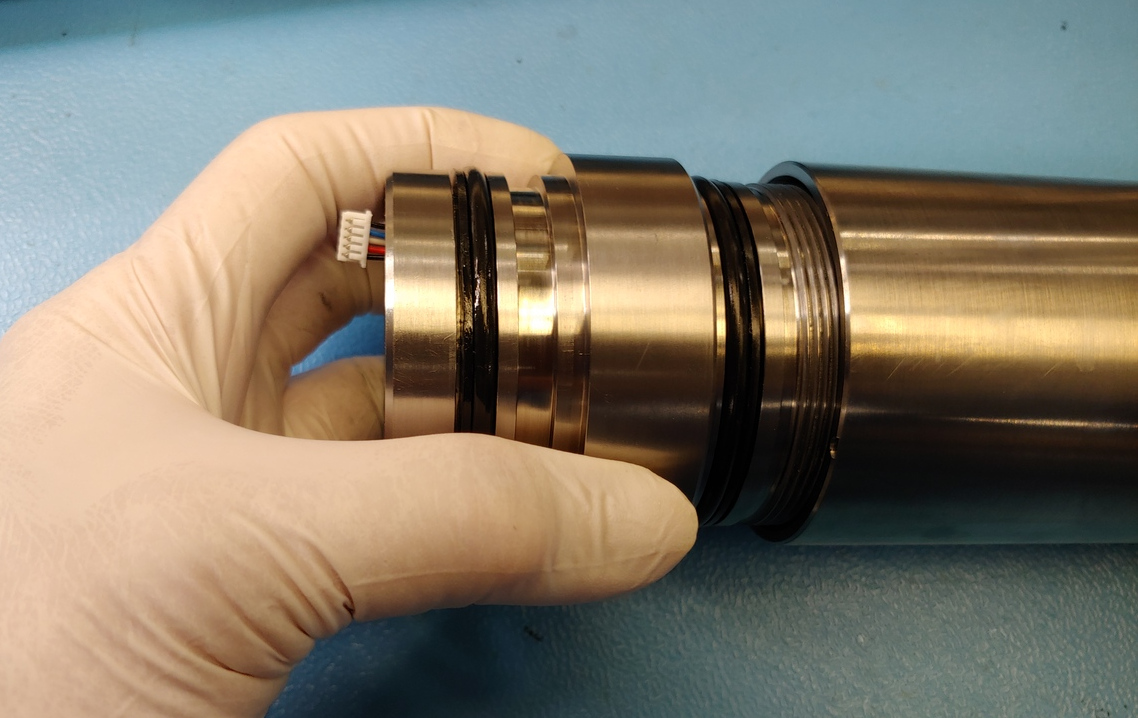

- Ensure that all o-rings that have been exposed are clean, lightly lubricated with silicone o-ring grease, and without cuts, nicks, excessive flashing or any other damage. Replace if necessary.

- Ensure that the backing o-rings are all on the "low pressure" side of the housing.

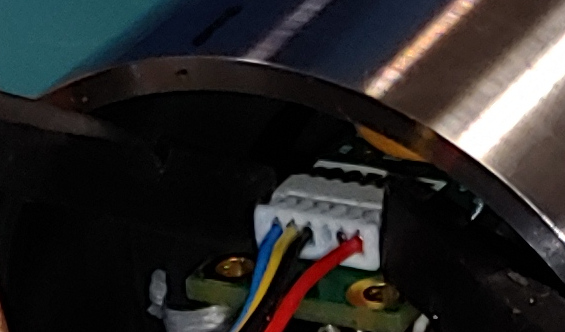

- Connect the 5-pin connector to the small lower board first.

- Connect the 6-pin connector to the larger board second.

- Connect the 2-pin connector.

- Ensure that two fresh desiccant containers are held in the exposed chassis.

- With a removable marker, mark the location of the dowel pin on the outside of its coupler. Also, mark the location of the mating dowel pinhole on the outside of its coupler.

- Gently push the two halves together taking care to not misalign and damage the o-ring. Use the two dowel pin marking locations (from step 6) to align the dowel pin to its hole.

- Push the nylon locking strap into the slot, with the chamfered end first. Ensure that the strap is pushed all the way in. This is best done with pliers.

Location of o-rings

Parker 2-225 N70 o-rings and 8-225 back-up rings are used at every joint in the housing. Only o-rings that are exposed during maintenance need to be checked before reassembly.

- O-rings must have no cuts, nicks or excessive flashing. If in doubt, replace the o-ring.

- O-rings should be slightly lubricated with silicone o-ring grease.

- When replacing o-rings near external threads, protect the o-rings by covering the threads with electrical tape temporarily.

- Backing o-rings should be placed on the low-pressure (inner) side of the o-ring, with their flat side against the o-ring groove in the Ti housing piece.